Smyth Composites Limited have specifically designed a range of GRP Dagger Boards to meet Network Rail’s requirement to replace old rotten wooden boards when they are either carrying out general improvements to station platform environments, or for when they are doing major works involving the cutting back of station canopies to allow for the new electrification system. Each board is normally supplied at between 1400 – 1500mm wide made up of 9 – 15 dagger blades.

Board Surface Finishes

These solid GRP boards are offered in a number of variants to meet individual stations specific requirements.

- Tongue and Groove finish

- Tongue and Groove to one face and flat finish to reverse

- Flat finish to both sides (with a wood-grain finish if required)

Dagger Board Thicknesses

Generally these boards are supplied from 6mm thick upwards. Obviously the thinner the board the lighter and more cost effective it will be, however in some instances, where a station has a “Listed” status, for example, the relevant heritage authority may insist on replacing the boards “like for like” as far as thickness is concerned.

End Profiles and “Running Profiles”

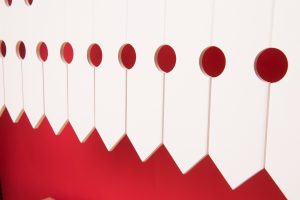

Smyth Composites have the ability to supply the GRP dagger boards with various “end profiles” as can be seen from the various images on this page. And as well as the dagger board panels Smyth Composites can supply GRP “running profile” either as flat fascia strips or more intricate molded profiles.

Colours

Although normally supplied in white, these GRP Dagger Boards (or fascia) can come in any RAL colour and in some circumstances in different colours to each face.

Fire Ratings

These panels can either be supplied as standard “general purpose” boards or they can be manufactured incorporating fire rated resins resulting in either BS 476 Pt7 Class II or Class 1 fire ratings.

Why use GRP Dagger Boards?

- Low Maintenance – avoiding regular downtime/costs

- Easy and quick to install – again saving on costs

- Impact Resistant

- Choice of colour, thickness, profiles

- Non-Conductive

- High levels of U.V. resistance – resists colour fade

- Manufactured to Required Specification