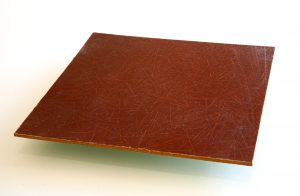

Our Phenolic, High Performance Fire Panel, is a composite sheet product consisting mainly of cured phenolic resin and glassfibre. It is one of the most effective cosmetic FIRE RESISTANT sheet materials available, producing relatively minute quantities of smoke and toxic fumes when exposed to fire – whist still retaining excellent physical properties at high temperatures.

Phenclad is ideal for cladding, lining, partitioning, panelling and many other applications. It is available in a wide range of colours and several surface finishes and may also be bonded to other materials to provide a wider range of applications.

Phenclad is relatively easy to handle and install using a variety of complimentary fixing systems. It is easily cleaned, has a graffiti resistant surface, is shatter-proof, has similar if not better physical attributes to other composites and is extremely cost effective. Phenclad can be drilled, sawn, cut and machined using standard tools and equipment.

Compared to other composite products, Phenclad panels are unique in the respect they’ve been tested and certified for use in high risk installation and have been deemed ‘fit for purpose’ in applications such as Offshore Installations and Underground Railway Stations.

Compared to other composite products, Phenclad panels are unique in the respect they’ve been tested and certified for use in high risk installation and have been deemed ‘fit for purpose’ in applications such as Offshore Installations and Underground Railway Stations.